Supplier Of Socket Weld Flange Wall Thickness, Socket Weld Flange Class 900,Socket Weld Flange Class 2500, Socket Weld Ring Joint Flange, Gasket For Socket Weld FlangeSocket Weld Flanges UK, PN16 Socket Weld Flange Dimensions,Socket Weld Flange Welding, 2 inch socket weld flange, 4 bolt socket weld flange, socket weld companion flange, socket weld tube flange, 6 inch socket weld flangeANSI/ASME B16.5 Socket Weld Flange SpecificationDimensions ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom DrawingsSize 1/2″ (15 NB) to 48″ (1200NB)Class150 LBS, 300 LBS,

Contacta ahora

ASME B16.5 SpecificationsSpecificationASME B16.5 FlangeType Of Industrial flangesBlind Flange/ Slip On Flange/ Weld Neck Flange/ Socket Weld Flanges/ RTJ Flanges/ Lap Joint Flanges/ Threaded/ Reducing FlangesFlanges Manufacturing MaterialStainless Steel, Brass, Bronze, Duplex Steel, Super Duplex, Incoloy, Alloy 20, Copper, Carbon Steel, Nickel Alloys, Tantalum, Cupro-Nickel Inconel, Monel, Titanium, Hastalloy, Alloy Steel.Type Of Pipe Flange MethodsForging/ Casting/ Rolling And CuttingANSI Flange Pressure ClassClass 150/ Class 300/ Class 400/ Class 600/ Class 600/ Class 900/ Class 1500/ Class

Contacta ahora

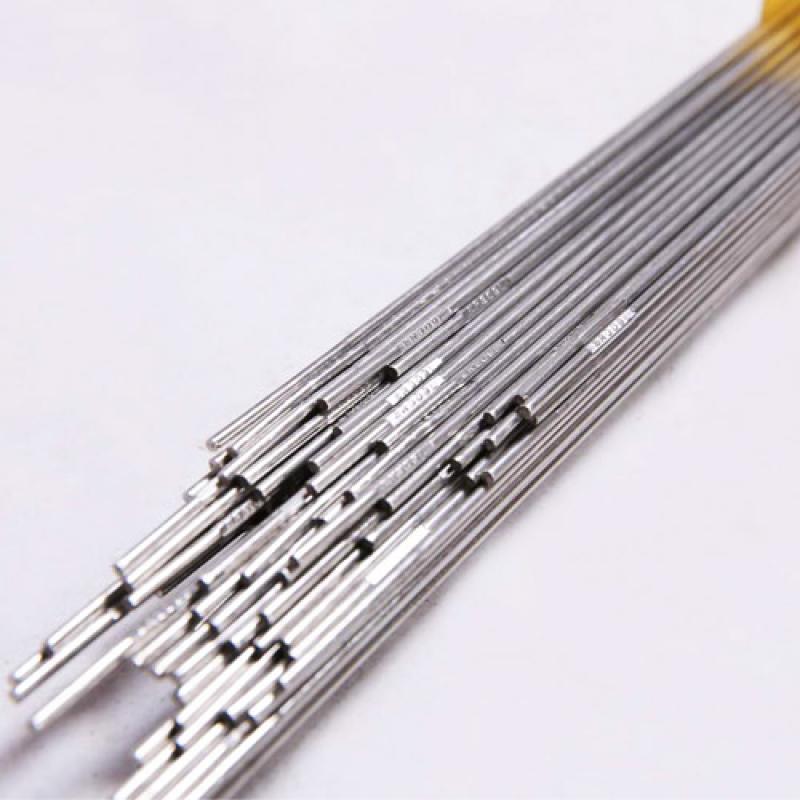

Products InfomationApplication:Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.It HAS excellent welding process performance, stable arc combustion, less spatter, beautiful weld forming, small stomatal sensitivity of weld metal, good all-position welding process, suitable for a wide welding current range.

Contacta ahora

Threaded flange refers to a flange that uses threads to connect to pipes. When designing, it can be handled as loose flange. The advantage is that there is no need for welding, and the additional moment to the cylinder or pipe when the flange is deformed is very small. The disadvantage is that the flange thickness is large and the cost is high.

Contacta ahora

Butt welding ring loose flangeThe purpose of using butt welding ring loose flange is to save materials. The flange plate is made of low-grade material, and the pipe part is made of the same material as the pipe, so as to save material.Butt weld ring loose flange:1. Cost saving. When the pipe material is special and expensive, the cost of welding flanges of the same material is high.2. It is inconvenient for welding or processing or requires high strength. Such as plastic pipes, glass steel pipes and the like.3. Easy to construct.

Contacta ahora

Stainless Steel Butt Weld ElbowPackaging Details:Standard seaworthy package or as your requiredPort :Tianjin or as your requiredProducts DescriptionProduct NameANSI B16.9 Butt Weld Stainless Steel 90 Degree LR ElbowSize1/2"-48"MaterialStainless SteelPackagingWooden Case/Wooden PalletsStandardANSI ,ASME, EN,DIN, JISRadiusLong, Short ThicknessSCH5S-SCHXXSOthersSpecial design available according to your requestProduct photoProduct Advantage:1.

Contacta ahora

Stainless Steel PipeFormWelded and Seamless in Round.ApplicationFluid & Decorative.Size RangeDN15 – DN600.Grades304/304L & 316/316L.321,309S,310S,347H,2205,2507,254SMO, Wall ThicknessSch 10S, 40S & 80S.FittingsButt Weld, Screwed & Socket Flanges (ANSI, Table E & Table D).ProcessingCut-to-length & polishing.The information provided is for standard stock product and does not encapsulate all available combinations.

Contacta ahora

ASTM A182 F304 304L F316 316L Stainless Steel Socket Welding FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time

Contacta ahora

Customized ANSI 150lb-2500lb 1/2"-72" SS WN Flanges Stainless Steel Weld Neck FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as neg

Contacta ahora

ASTM A182 F11 F22 F5 F304 F316L F53 Stainless Steel Duplex Stainless Steel Slip on Flange So RF Flange Weld Neck Flange Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as

Contacta ahora

Metallographic structure of Hastelloy B-3 Hastelloy B-3 has a face-centered cubic lattice structure.

Contacta ahora

We mainly produce the Carbon and Alloy Steel Flanges, Nickel Alloy Steel Flanges, Stainless Steel Flanges. Here are the main types of the Flanges that we can supply for you.

Contacta ahora

Internal Stainless steel forged thread flangeThe threaded flanges are connected to the ends of the two pipes, and each flange is installed.

Contacta ahora

slip on flange ASME B16.5 ss304L ss316L flanges plate flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 work

Contacta ahora

Pipe Fitting Direct: Spectacle Blind Flange 3-1/2'' 600LB Stainless Steel 304L 321 316l ASTM A105 ASME B16.9 Eight 8 Word FlangesItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice Item

Contacta ahora

Incoloy 925 precipitation strengtheningBy aging treatment, the second phase (γ', γ", carbide, etc.) is precipitated from the supersaturated solid solution to strengthen the alloy. γ' phase is the same as the matrix, which is face-centered cubic structure, with similar dotting constants to the matrix, and co-grid with the crystal, so the γ phase can be uniformly precipitated in the matrix in the form of fine particles, impeding dislocation movement, and producing significant strengthening effect.

Contacta ahora

Using 316L stainless steel, no post-weld annealing is required.

Contacta ahora

Flat Welded Flange With Neck XINYUAN has been engaged in theStainless steel production and supply of various flanges and pipe fittings for more than 15 years. Our flagship products include pipes, flanges, elbows, elbows, tees, reducers, caps, forged fittings, bolts and nuts, washers, profiles and other fittings that meet all national and internationally recognized standards.

Contacta ahora

A 310s stainless-steel bar is a sort of stainless steel alloy that carries high degrees of chromium, nickel, and a mild quantity of carbon. the "310s" designation refers back to the unique grade of stainless-steel and indicates that it contains 25-28% chromium and 19-22% nickel.310s chrome steel is known for its outstanding oxidation resistance at high temperatures and its potential to face up to thermal biking.

Contacta ahora

C-276 alloy welding performance and common austenitic stainless steel is similar to using a welding method for welding C-276 before, we must take measures to make the corrosion resistance of the weld and heat affected zone the smallest decline, such as tungsten gas shielded arc welding (GTAW), gas metal arc welding (GMAW), submerged arc welding or some other can make the weld and heat affected zone the smallest decline in corrosion resistance welding method.

Contacta ahora

Flat welding flanges are suitable for pipeline systems with relatively low pressure levels and no serious pressure fluctuations, vibrations and shocks.

Contacta ahora

The 304l stainless-steel i-beam is a chromium-nickel grade of metallic. it includes 8 percentage nickel and 18 percent chromium. it's miles a with ease machinable metallic that has remarkable formability and weldability. it has desirable corrosion-resistance and is even able to face up to intergranular corrosion, which could arise after welding or stress relieving. as it has a low content material of carbon, it could be accurately utilized in maximum welded construction operations that use temperatures no better than 800 tiers f.

Contacta ahora

ER308,ER308L,ER308Si,ER308LSi,ER309,ER309L,ER310,ER316,ER316L;AWS: A5.9Conforms to Certification: AWS A5.9 ASME SFA A5.9Weld Process Used for Mig (GMAW) and Submerged Arc (SAW)AWS Chemical CompositionC = 0.08 maxCr = 19.5 – 22.0Ni = 9.0 – 11.0Mo = 0.75 maxMn = 1.0 – 2.5Si = 0.30 – 0.65P = 0.03 maxS = 0.03 maxCu = 0.75 maxAvailable SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mi

Contacta ahora