Type 301 is an austenitic chromium-nickel stainless steel that is available in the annealed and cold worked conditions. In the annealed condition, Type 301 offers the highest level of stretch formability of any stainless steel and in the heavily cold worked condition offers the highest strength level of any 300 series stainless steel. Type 301 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contacta ahora

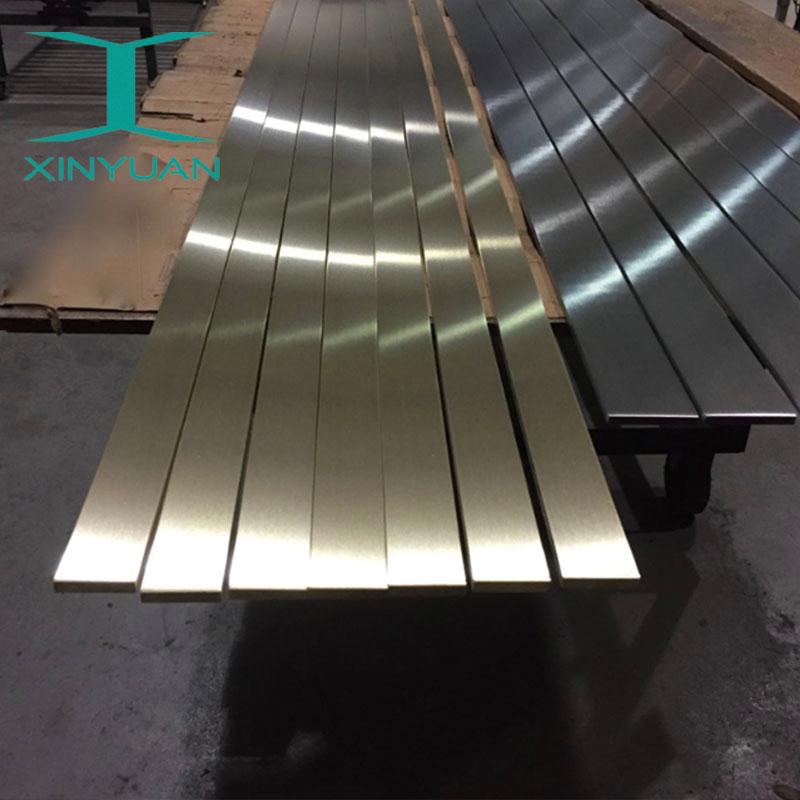

316L Super Austenitic Stainless Steel316L Super Austenitic Stainless Steel Scope of application:Corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, which can be used in harsh conditions; Excellent work hardening (non-magnetic).

Contacta ahora

Ha alloy, duplex stainless-steel 316 304 and different stainless steel substances, the sort of its commercial enterprise is steel plate, steel pipe, round steel, and so on., may be custom designed in keeping with patron name for processing.316 stainless steel, 18CR-12Ni-2.5Mo due to the addition of Mo, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength is particularly good, can be used under harsh conditions; Excellent work hardening (no magnetic).

Contacta ahora

316L stainless steel hexagonal bar Features:1) Cold rolled products have good gloss and beautiful appearance;2) Excellent corrosion resistance, especially pitting corrosion resistance;3) Excellent high temperature strength4) Excellent work hardening (weak magnetic properties after machining)5) No magnetic properties in solid solution state;6) Compared with 304 stainless steel, the price is higher.3, application scope: pipeline, heat exchanger, food industry, chemical industry, etc.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.M

Contacta ahora

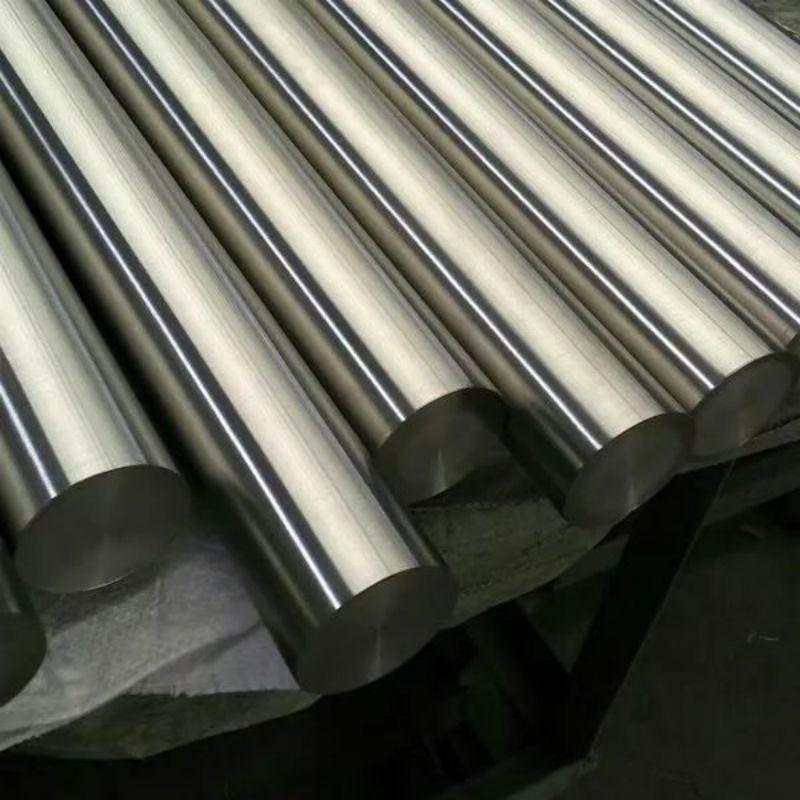

Stainless steel bar specification, materialMaterial :304, 304L, 321, 316, 316L, 310S, 630, 1Cr13, 2Cr13, 3Cr13, 1Cr17Ni2, duplex steel, antibacterial steel and other materials!304(18Cr-8Ni) material: as a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other thermal processing, no heat treatment hardening phenomenon (no magnetic, they use temperature -196℃~800℃).

Contacta ahora

2507 dual-phase steel density: 8.03g/cm3, melting point: 1300-1390 ℃, magnetic: noneHeat treatment: heat preservation between 1000-1052℃ for 1-2 hours, rapid air cooling or water cooling.Mechanical properties: tensile strength: σb≥795Mpa, yield strength σb≥550Mpa: elongation: δ≥15%, hardness ≤310 (HB)Product Parameter:ItemStandardMaterialStainless SteelASTM201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329,405, 409, 430, 434, 444, 403, 410, 420, 440A, etc.EN1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845,

Contacta ahora

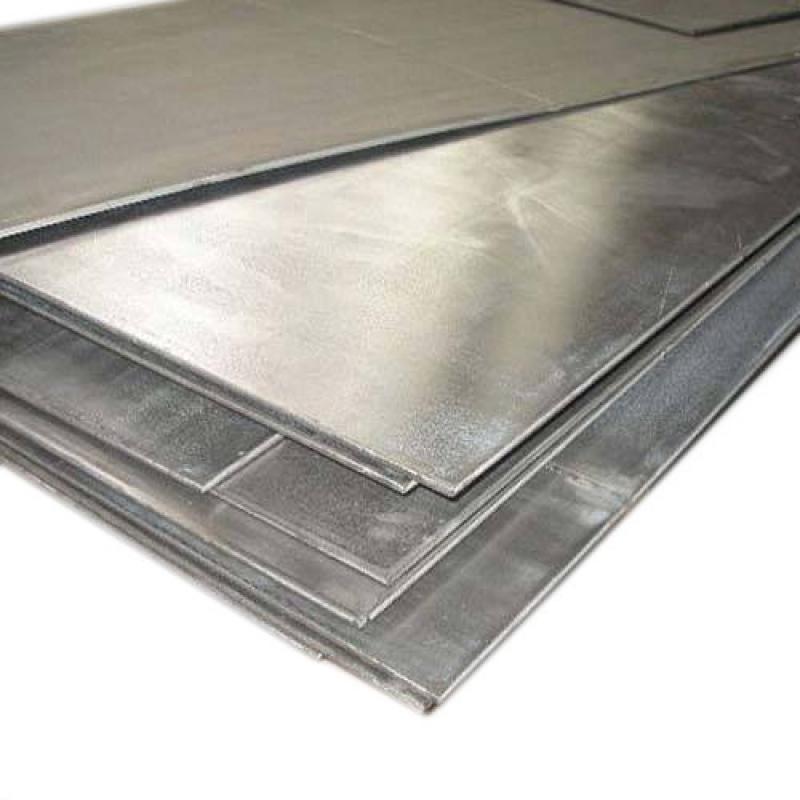

ProductStainless Steel Sheet/Plate/CoilSurface FinishBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, EmbossedTechniqueHot Rolled / Cold RolledStandardGB JIS ASTM ASME ENSteel Grade200 series: 201 202300 series: 301 304 304L 309 310 310s 316 316L 321400 series: 409 410 410S 420 430ColorStandard RAL color:red,bule,white,grey,brick,etc.Stock Dimension0.5mm-4mm x 1220mm/1500mm x 2440mm/2500mm;5mm-25mm x 1220mm/1500mm x 2440mm/2500mm/6000mm;8mm-80mm x 1500/1800/2000mm/2500 x 6000mm;cut to size according to customers' demandsServiceOEM, customized processing service, customized fabrication by drawingsProcessi

Contacta ahora

Stainless Steel FlangeFeatures of stainless steel products1) High strength;2) Excellent machinability3) Hardening occurs after heat treatment;4) Magnetic;5) Not suitable for harsh corrosive environment.Scope of applicationGeneral blades, mechanical parts, bolts, nuts, Class 1 tableware (spoons, forks, knives, etc.).ItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Proce

Contacta ahora

Stainless Steel 317 Square Bars & Rods have excellent yield strength and tensile strength, which is suitable for cold working and annealed condition appliance. It has nickel and low carbon content to provide high formability and excellent corrosion resistance to alkaline compounds. SS 317 Bars & Rods is austenitic stainless steel non-magnetic in nature, less conductivity to electricity, and less brittle at low temperature.

Contacta ahora

Type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304. Nickel is replaced by additions of manganese and nitrogen. It is non-hardenable by thermal treatment, but may be cold worked to high tensile strengths. Type 201 is essentially nonmagnetic in the annealed condition and becomes magnetic when cold worked.

Contacta ahora

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contacta ahora

Chinese 2Cr13 steel (20Cr13) is a martensitic stainless steel with magnetic properties, good corrosion resistance and high hardness in the quenched state.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 et200series:201,202,202cu,204300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti, 317L,321,347400series:409,409L,410,420,430,431,439,440,441,444Others:2

Contacta ahora

Alloy Inconel 625 is a low-carbon nickel-chromium-molybdenum alloy with excellent breadability to various corrosive media, non-magnetic; good strength, toughness and excellent fatigue resistance in environments ranging from low temperatures to 1093°C (2000°F), thanks to the low carbon content and solid solution treatmentTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy:

Contacta ahora

201 Stainless Steel Square Bar,belongs to the chrome - nickel - manganese austenitic stainless steel, magnetic low 200 series stainless steel round bar .Application of 201 stainless steel square bars: oil and gas pipeline; chemical industry; plumProduct Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S

Contacta ahora

super duplex 2507 round bar is an alloy which has been designed for applications that demand exceptional tensile strength and superior resistance to corrosion as well.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contacta ahora

Incoloy N08800, N08810, N08811 Coils are available in various sizes, dimensions, shapes, and thickness. Incoloy 800 Coils contains a combination of Iron, Nickel and Chromium elements which enhance its qualities such as exposure to high temperatures, excellent resistance to oxidation, carburization at high temperatures, moderate strength and many more.We also focus on packing and shipping of Coils to deliver them safely. We use suitable packing material to pack Incoloy 800 Coils, and fast way of transportation to ensure damage-free and on-time delivery at the client’s locations.

Contacta ahora

Incoloy Alloy A-286 is readily fabricated by standard procedures for stainless steel and alloys.

Contacta ahora

Nickel Alloy Incoloy 800HT PipeIncoloy 800 HT is composed of more aluminum and titanium. This gives 800 HT even greater resistance to high temperatures. Incoloy 800 HT is recommended for temperatures exceeding 1100° F, often in instances where stainless steels are subject to crack and creep. The Incoloy alloys are commonly used in high temperature environments, such as industrial furnaces, chemical and nuclear vessels, and heat-treating equipment.

Contacta ahora

The Incoloy 800HT has further modified the combined titanium and aluminum levels (.85-1.20%) to ensure optimal high-temperature performance. The nickel alloy is dual certified (800H/HT) to combine the characteristics of both forms.

Contacta ahora

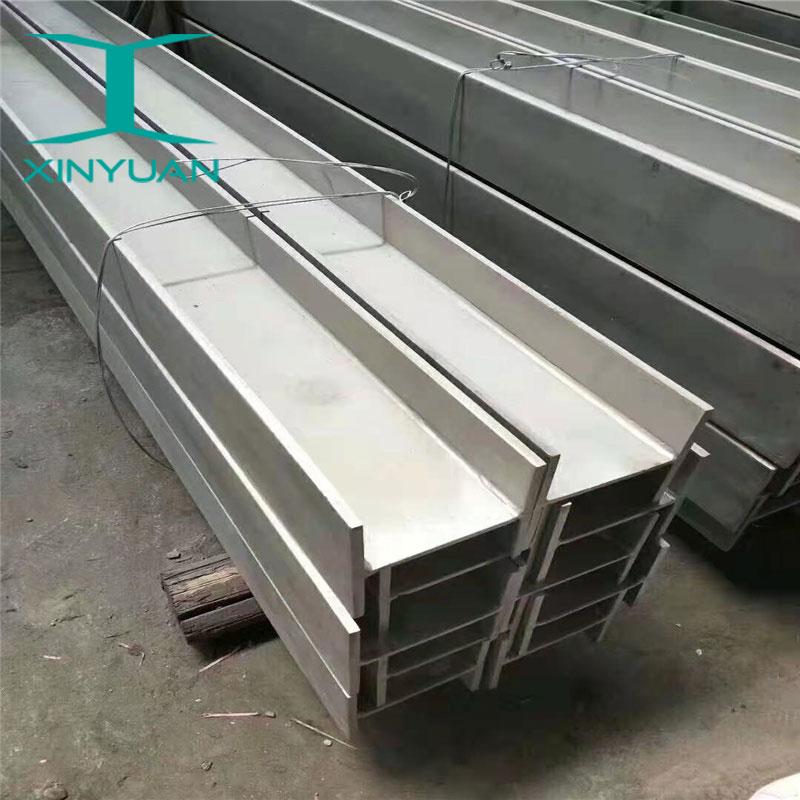

Its specifications are expressed in millimeters side width × side width × side thickness. For example, "225x25x3" refers to an equilateral stainless steel Angle with a side width of 25mm and a side thickness of 3mm. It can also be represented by the model number, which is the number of centimeters of the width of the side, as in 23#. The size of different side thicknesses is not indicated in the same model, so the side width and side thickness of stainless steel Angle are filled in the contract and other documents to avoid using the model alone.

Contacta ahora

Company Profile.Since its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.). Duplex stainless steel (2205, 2507, 2520).

Contacta ahora

Inconel 825 PipeInconel 825 Pipes are constructed from primary factors like iron, nickel, and chromium, which supply the primary resistance to rusting and pitting in ordinary temperatures. Inconel 825 Pipe has some introduced factors in small parts like molybdenum, titanium, and copper which provides greater substance to the product and will increase its workability even in marine conditions.

Contacta ahora

Inconel 718 PlateInconel 718 Plate is a precipitation hardening super alloy that combines high strength and oxidation resistance with superior weldability.

Contacta ahora

Incoloy 800H Nickel Base Alloy Pipe Application:National defense, astronautics, transportation, equipment manufacture, shipping, petroleum, nuclear power industry, oil and gas industry, and chemical industry etc.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500

Contacta ahora