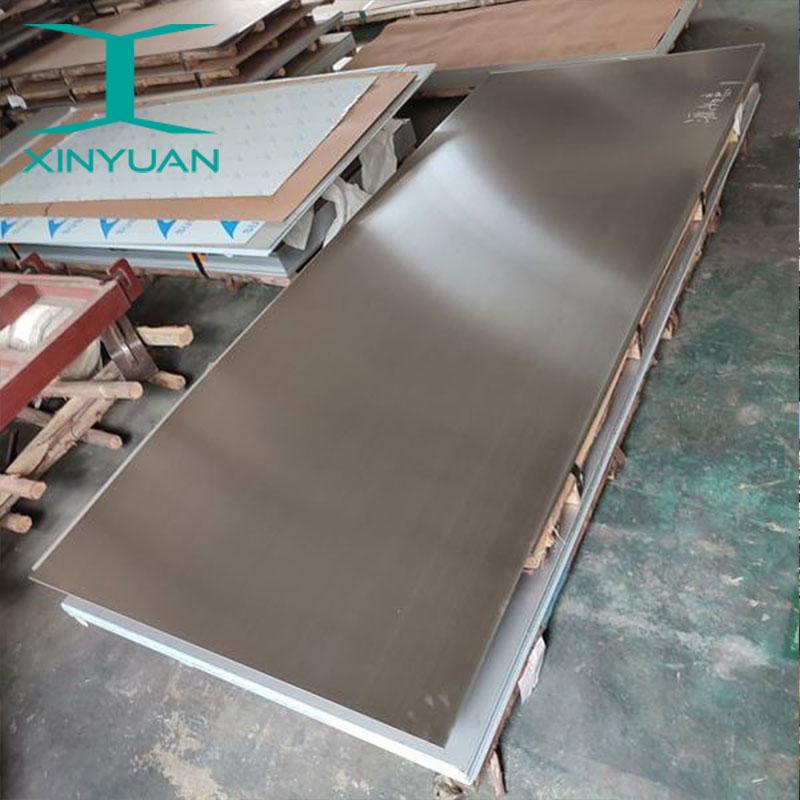

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Type 304 can be easily roll-formed or bent, and its excellent corrosion resistance and weldability make it one of the most popular grades. Type 316 is a high corrosion resistance alloy, providing greater resistance to pitting-type corrosion. Typical uses for Type 316 include marine, chemical, paper, textile, and food service applications, such as a stainless steel back splash.

Contacta ahora

These grades of austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments.

Contacta ahora

Stainless steel with 12%~30% chromium and ferritic matrix of body - centered cubic lattice at high temperature and room temperature. This kind of steel generally does not contain nickel, some contain a small amount of molybdenum, titanium or niobium and other elements, with good oxidation resistance, corrosion resistance and chloride corrosion cracking resistance.

Contacta ahora

254SMO is an austenitic stainless steel. Because of its high molybdenum content, it has very high resistance to spot corrosion and crevice corrosion. Main ingredients:254 smo carbon (C) 0.02 or less, manganese (Mn) of 1.00 or less, nickel (Ni) 17.5 ~ 18.5, silicon (Si) of 0.8 or less phosphorus (P) of 0.03 or less, sulfur (S) of 0.01 or less, chromium (Cr) 19.5 ~ 20.5, copper (Cu) 0.5 ~ 1.0, molybdenum (Mo) 6.0 ~ 6.5 National standards: UNS S31254, DIN/EN 1.4547, ASTM A280, ASME SA-240 Welding material: ERNiCrMo-3 wire, ENiCrMo-3 electrode Product Name254smo st

Contacta ahora

Product SpecificationUnit Pipe Length3 meter, 6 meter, 9 meter, 18 meterMaterialStainless SteelProduct DescriptionGradeTensileUltimate/MinYield/MinElongation/Min-KSIMPAKSIMPA%304755153020535304L704852517035These grades of austenitic stainless steels are the most versatile and widely used stainless steels.

Contacta ahora

Incoloy N08800, N08810, N08811 Coils are available in various sizes, dimensions, shapes, and thickness. Incoloy 800 Coils contains a combination of Iron, Nickel and Chromium elements which enhance its qualities such as exposure to high temperatures, excellent resistance to oxidation, carburization at high temperatures, moderate strength and many more.We also focus on packing and shipping of Coils to deliver them safely. We use suitable packing material to pack Incoloy 800 Coils, and fast way of transportation to ensure damage-free and on-time delivery at the client’s locations.

Contacta ahora

Type 301 is a chromium nickel austenitic stainless steel capable of attaining high strengths and ductility by cold working. It is not hardenable by heat ...Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contacta ahora

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Stainless steel sheet is to be had in kind 304 and sort 316. type 304 may be without problem roll-original or bent, and its great corrosion resistance and weldability make it one of the maximum famous grades.

Contacta ahora

202 stainless steel is one of the 200 series of stainless steel, gb model is 1Cr18Mn8Ni5N. 200 series stainless steel belongs to low nickel high manganese stainless steel, nickel content, manganese content of about 8%, is a section of nickel stainless steel.Chemical composition/%BrandCSiMnPSNiCrMoCuNother202≤0.15≤1.0≤7.5~10.0≤0.060≤0.034.00~6.0017.0~19.0----≤0.25BrandH treatmenteatThe yield strengthMpaTensile strengthMpaModulus of elasticity psiHBSHRBHV2021010~1120Fast cooling≥275≥520≥400000≤207≤95≤218Packaging & Shipping

Contacta ahora

Stainless steel sheet is available in kind 304 and sort 316. type 304 may be easily roll-formed or bent, and its incredible corrosion resistance and weldability make it one of the maximum popular grades. Type 316 is a excessive corrosion resistance alloy, providing extra resistance to pitting-kind corrosion.

Contacta ahora

Stainless Products supplies stainless steel seamless tube per ASTM A 213, ASTM A 269 and ASTM A 511. We supply common grades of stainless steel such as 304/304L and 316/316L in standard tube sizes and wall thicknesses.

Contacta ahora

Application example: The exhaust valve of diesel engine for ship and tank is mainly made by Nimonic 80A forging. Nimonic 80A has high heat resistance, high strength at high temperature, large deformation resistance, increasing the difficulty of forging forming.

Contacta ahora

PROFILE201 stainless steel has a certain acid resistance, alkali resistance, high density, polishing no bubble, no pinhole and other characteristics, is the production of all kinds of watch case, watchband bottom cover quality materials. Mainly used for decorative pipe, industrial pipe, some shallow stretching products.201 Stainless steel coil price is lower compared to other grades of stainless steels and all metallic products in general.

Contacta ahora

2205 Duplex Stainless Steel PlateDuplex 2205 is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. It is the most widely used duplex stainless steel grade and is characterized by high yield strength, double that of the standard austenitic stainless steel grades.

Contacta ahora

ER410 H1Cr13 Y410 510 25 13Cr steel, the deposited metal is 13Cr, with high hardenability, excellent oxidation resistance and corrosion resistance at high temperature, suitable for welding of AISI410 or 420.ER410 flux-cored stainless steel wire Application: used for welding 410 or 420 series stainless steel, with high hardening, high temperature oxidation resistance, corrosion resistance, used in petroleum refining and chemical industry and surfacing repair, such as 12Cr13 (sus410)Products DescriptionWarranty3 yearsCustomized supportOEM, ODMPlace of OriginChinaBrand NameXINYUANModel NumberER41

Contacta ahora

201 stainless steel, has a certain acid resistance, alkali resistance, high density, polishing no bubble, no pinhole and other characteristics, is the production of all kinds of watchcase, watchband bottom cover quality materials. Mainly used for decorative pipe, industrial pipe, some shallow stretching products. This model belongs to the grade of nickel-saving steel, which has magnetism after cold working and can be used in railway vehicles.201 stainless steel has certain acid and alkali resistance, high density, no bubbles, no pinholes, etc.

Contacta ahora

Product DescriptionProductStainless Steel Sheet/Plate/CoilSurface FinishBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, EmbossedTechniqueHot Rolled / Cold RolledStandardGB JIS ASTM ASME ENSteel Grade200 series: 201 202300 series: 301 304 304L 309 310 310s 316 316L 321400 series: 409 410 410S 420 430ColorStandard RAL color:red,bule,white,grey,brick,etc.Stock Dimension0.5mm-4mm x 1220mm/1500mm x 2440mm/2500mm;5mm-25mm x 1220mm/1500mm x 2440mm/2500mm/6000mm;8mm-80mm x 1500/1800/2000mm/2500 x 6000mm;cut to size according to customers' demandsServiceOEM, customized processing service, customized fabrication

Contacta ahora

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.DetailsA286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium.

Contacta ahora

Alloys Incoloy 800H and Incoloy 800HT are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel, and 22% chromium. These two grades are variations of the base grade 800 and are referred to by the tradenames Incoloy 800H and Incoloy 800HT and the universal designation UNS N08810 and N08811, respectively.

Contacta ahora

Stainless Steel 410 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F.

Contacta ahora

LDX 2101* is a duplex (austenitic-ferritic) stainless steel with relatively low contents of alloying elements. The grade has high mechanical strength, similar to that of other duplex grades. Its good corrosion resistance is on par with that of most standard stainless steel grades.

Contacta ahora

Nickel Alloy Incoloy 800HT PipeIncoloy 800 HT is composed of more aluminum and titanium. This gives 800 HT even greater resistance to high temperatures. Incoloy 800 HT is recommended for temperatures exceeding 1100° F, often in instances where stainless steels are subject to crack and creep. The Incoloy alloys are commonly used in high temperature environments, such as industrial furnaces, chemical and nuclear vessels, and heat-treating equipment.

Contacta ahora

We specialize in stainless steel and high nickel exotic alloys, and hold stock to ensure short lead times. Our quick delivery alloys include 201,301,302,303,304,304L,316,316L,321,308,308L,309,309L,309S,309H,310,310S ,410,430,2205Series.We draw round wire into finished sizes from .001” to .312”. Shaped and flattened wire are available upon request Our wire is available in a wide range or versatile packaging options ranging from coils and carriers to spool and reels.

Contacta ahora

Inconel600 alloy has satisfactory thermal strength and high plasticity below 800C.

Contacta ahora