Types 309 and 309S are austenitic chromium-nickel stainless steels that provide excellent corrosion resistance and heat resistance plus good strength at room and elevated temperatures. Type 309S is identical to Type 309 except for a lower carbon content that minimizes carbide precipitation and improves weldability.

Contacta ahora

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Type 304 can be easily roll-formed or bent, and its excellent corrosion resistance and weldability make it one of the most popular grades. Type 316 is a high corrosion resistance alloy, providing greater resistance to pitting-type corrosion. Typical uses for Type 316 include marine, chemical, paper, textile, and food service applications, such as a stainless steel back splash.

Contacta ahora

Stainless Steel 410 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F.

Contacta ahora

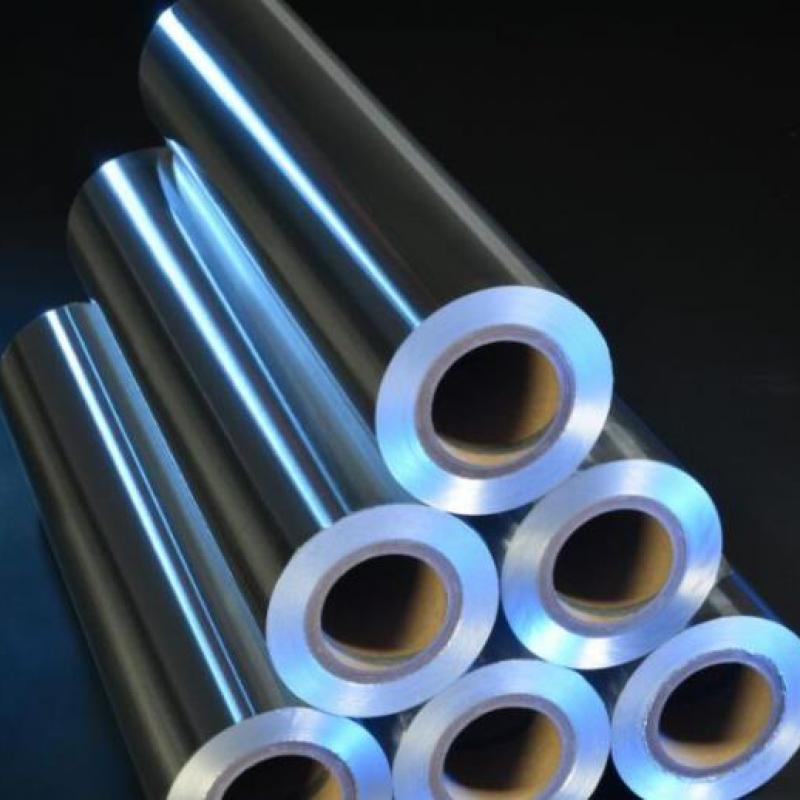

Through integrated production control, stainless steel foil that is excellent in etching properties and press formability, in addition to ultimately high thickness accuracy, strength, and spring characteristics. Stainless Steel FoilStainless steel foil is produced through the highly accurate rolling of stainless steel to be as thin as 100 mm, thus it has excellent flexibility, lightweight characteristics, and corrosion resistance.

Contacta ahora

SAF 2507 offers high compressive strength, impact strength, low coefficient of thermal expansion and high thermal conductivity.These characteristics are applicable to many structural and mechanical components.SAF 2507 has high impact strength and is not suitable for prolonged exposure to temperatures higher than 570°F, which may reduce toughness.2507 stainless steel composition content.GradeCMnSiPSCrMoNiN2507Min.Max.≤0.03≤1.2≤0.80≤0.035≤0.0224-263-56-80.24-0.32Chemical CompositionENASTM/UNSCNCrNiMoCOMPOMENT11.43013040.0418.18.321.4307304L0.0218.18.331.45413210.0417.39.1Ti0.2441.45503470.0517.5

Contacta ahora

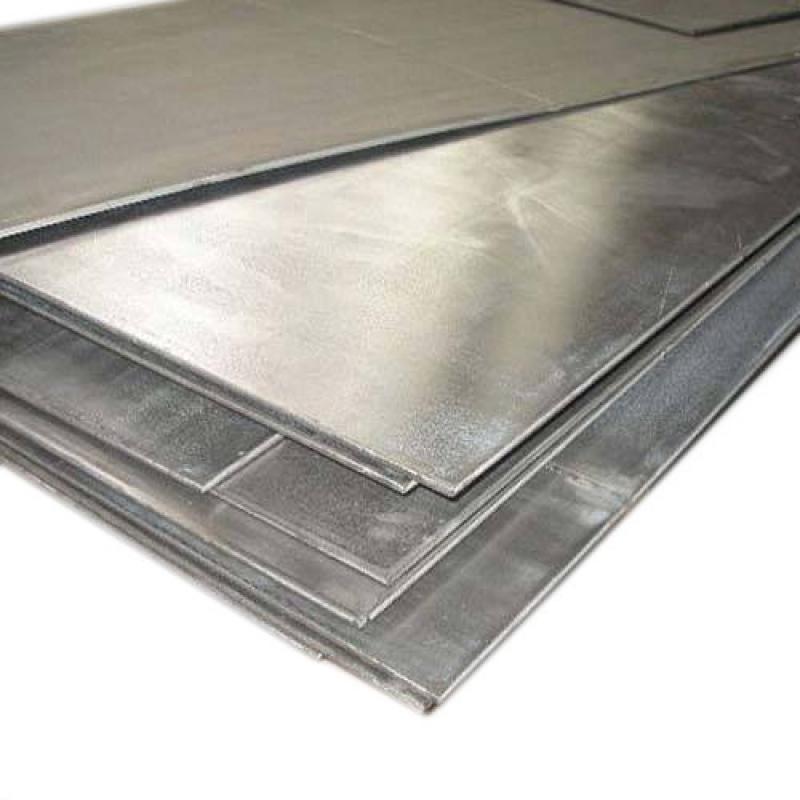

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Stainless steel sheet is to be had in kind 304 and sort 316. type 304 may be without problem roll-original or bent, and its great corrosion resistance and weldability make it one of the maximum famous grades.

Contacta ahora

Stainless steel sheet is available in kind 304 and sort 316. type 304 may be easily roll-formed or bent, and its incredible corrosion resistance and weldability make it one of the maximum popular grades. Type 316 is a excessive corrosion resistance alloy, providing extra resistance to pitting-kind corrosion.

Contacta ahora

The grade of austenitic stainless steel is versatile and is widely used stainless steel. It is exhibiting high corrosion resistance for the wide range of highly corrosive environments. The type 304 and 304L stainless steel grade pipe is also exhibiting good machinability and is also having excellent weldability feature without or by adding the filler metals.Stainless Steel 304/304L Pipe & Tube is versatile stainless steel which is popularly used for making the tools or the parts that require excellent performance (formability and corrosion).

Contacta ahora

Stainless steel beams can be extruded, hot rolled or laser fused products. Stainless steel's high strength, toughness and corrosion resistance make it an excellent material for structural support applications in corrosive environments. Its bactericidal and disinfecting capabilities make stainless steel beams ideal structural support for food service, food processing and pharmaceutical applications, elevators, joists, building construction, trailer and truck bed frames, mezzanines and more.

Contacta ahora

Stainless steel plate surface smooth, high plasticity, toughness and mechanical strength, acid, alkaline gas, solution and other media corrosion. It is an alloy steel that is resistant to rust, but not absolutely resistant to rust.

Contacta ahora

Products Description Stainless-steel plate is detection and shaping need to be off-line processing.

Contacta ahora

MaterialType 304 Stainless SteelShapeformCoilPreparationPaper InterleavedVinyl MaskedThickness26 gaugeThickness0.0235 inches0.5969 mmSize48 x CoilWidth48Sheet Weight per Unit Area0.76 lbs/ft²3.71032 kg/m²FinishNo. 2BNo. 3No. 4ConditionCold Rolled AnnealedNominal Composition0 to 0.25% Carbon1.00% Max. Silicon2.00% Max.

Contacta ahora

Stainless steel 316l din 1.4404 1.4435 welded pipes aenhance great weldability in addition to great corrosion resistance and excellent strength properties. These welded pipes are formed with optimum quality of stainless steel material.

Contacta ahora

410 Stainless Steel Checker Plate410 stainless steel contains 0.15% carbon and 13% chromium. It is a semi martensitic stainless steel. After quenching and tempering, it has high strength and toughness. It has good corrosion resistance and machining performance in a weak corrosive medium with a temperature not exceeding 30 degrees. It also has rust and corrosion resistance in wet atmosphere and fresh water, and has high thermal stability below 700 ℃.

Contacta ahora

These grades of austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments.

Contacta ahora

17-4 ph Stainless Steel is a precipitation hardening martensitic stainless steel. Typical 17-4 ph usage is seen in applications requiring high strength and a modest level of corrosion resistance. Strength and toughness desired can be manipulated by temperate range in the heat treatment process.

Contacta ahora

317l bars & rods is providing better creep, pressure to rupture, high tensile energy, and weldability. due to first-rate yield electricity, it has great thermal stability that can be utilized in accelerated temperature service. it has advanced corrosion resistance to corrosive acids together with acetic, formic, sulfurous, citric, and tartaric acid.

Contacta ahora

Inconel 718 PlateInconel 718 Plate is a precipitation hardening super alloy that combines high strength and oxidation resistance with superior weldability.

Contacta ahora

Alloy Inconel 625 is a low-carbon nickel-chromium-molybdenum alloy with excellent breadability to various corrosive media, non-magnetic; good strength, toughness and excellent fatigue resistance in environments ranging from low temperatures to 1093°C (2000°F), thanks to the low carbon content and solid solution treatmentTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy:

Contacta ahora

Our variety of wire made of stainless steel aren't best recognized for their range but also are regarded for their excellent quality, lengthy lifestyles and really reasonable fees.

Contacta ahora

Our variety of wire made of stainless steel aren't best recognized for their range but also are regarded for their excellent quality, lengthy lifestyles and really reasonable fees.

Contacta ahora

430 stainless steel is a type of ferritic stainless-steel that consists of chromium, which gives it its corrosion-resistant properties. the primary alloying element in 430 stainless-steel is chromium, generally starting from 16 to 18 percentage. it additionally has a low carbon content material, which improves its weldability.430 stainless-steel bars are generally utilized in various packages due to their desirable mixture of corrosion resistance, formability, and affordability.

Contacta ahora

Products InfomationApplication:Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.It HAS excellent welding process performance, stable arc combustion, less spatter, beautiful weld forming, small stomatal sensitivity of weld metal, good all-position welding process, suitable for a wide welding current range.

Contacta ahora

Product name :316 stainless steel bar, 304 stainless steel bar, 316 stainless steel bar. Grade :0Cr17Ni12Mo2, main material 316, 316L, 310, 310S, 304, 304L, 303 and so on.1, summary: Mo(2~3%), excellent pitting resistance, excellent creep strength at high temperature.2, features :1, cold rolled product appearance gloss is good, beautiful; 2, add Mo, corrosion resistance, especially excellent pitting resistance; 3.

Contacta ahora