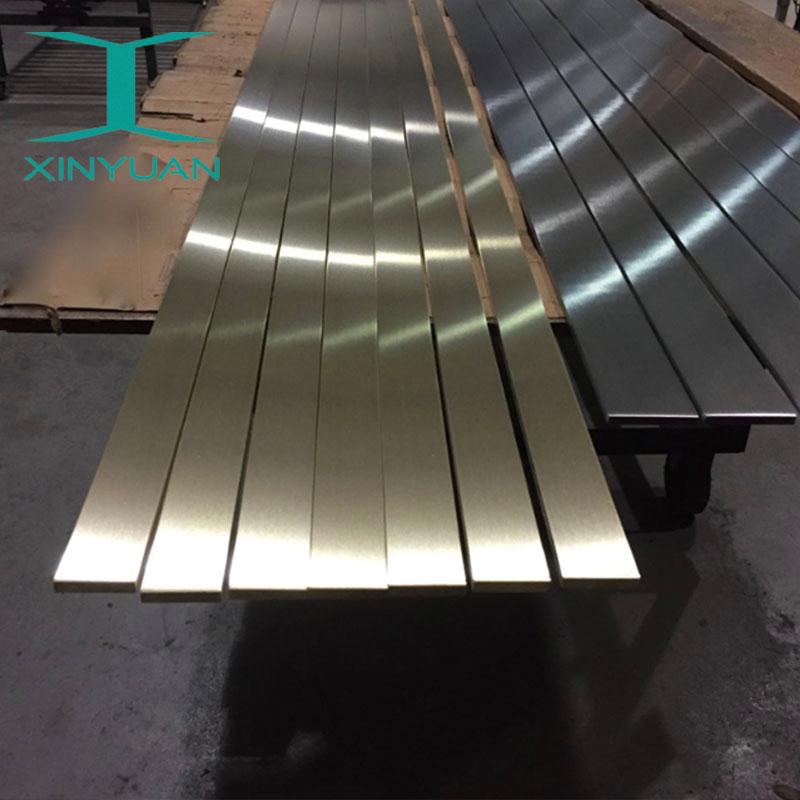

We Provide Quality Goods With Affordable Cost That Meets Budget Restraints Of Our Clients. Xin Yuan Supply with Competitive Domestic Stainless Steel plate in Regular and Special Size. Meet all needs。Support customization。Factory direct sales。Inventory direct sales。

Contacta ahora

Inconel 625 tubeInconel 625 tube is a nickel-chromium-molybdenum stable answer reinforced alloy with a nominal chemical composition of 61% nickel, 22% chromium, and 9% molybdenum. Inconel 625 tube is regularly referred to through the tradename Inconel 625 and the everyday designation UNS N06625.

Contacta ahora

17-4 ph Stainless Steel is a precipitation hardening martensitic stainless steel. Typical 17-4 ph usage is seen in applications requiring high strength and a modest level of corrosion resistance. Strength and toughness desired can be manipulated by temperate range in the heat treatment process.

Contacta ahora

Company ProfileSince its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.). Duplex stainless steel (2205, 2507, 2520).

Contacta ahora

1) Test methods.① Tensile test method. Commonly used standard test methods are GB/T228-87, JISZ2201, JISZ2241, ASTMA370, ГОСТ1497, BS18, DIN50145, etc..② Bending test method. Commonly used standard test methods are GB/T232-88, JISZ2204, JISZ2248, ASTME290, ГОСТ14019, DIN50111, etc.(2) performance indicators: the test items to assess the performance of angle steel are mainly tensile test and bending test.

Contacta ahora

Type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304. Nickel is replaced by additions of manganese and nitrogen. It is non-hardenable by thermal treatment, but may be cold worked to high tensile strengths. Type 201 is essentially nonmagnetic in the annealed condition and becomes magnetic when cold worked.

Contacta ahora

Using 316L stainless steel, no post-weld annealing is required.

Contacta ahora

Inconel alloys are suited to service in extreme conditions exposed to higher pressure and also kinetic energy because of their oxidation- and then corrosion-resistant properties.

Contacta ahora

We produce and distribute hot rolled and laser fused stainless steel angles at some point of the area in each imperial and metric sizes. Please pick out the catalog on your location under to view a listing of to be had elegant size angles. We're a profile answers employer, and custom shapes, sizes and alloys are to be had upon request.In case you do now not see what you are searching out, please touch us, and our skilled frame of workers will help guide you along side your custom profile needs.Products DescriptionProduct namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM,

Contacta ahora

We produce and distribute hot rolled and laser fused stainless steel angles during the arena in both imperial and metric sizes. Please pick out the catalog on your location underneath to view a listing of available fashionable size angles. We are a profile solutions enterprise, and custom shapes, sizes and alloys are to be had upon request.If you do now not see what you are looking for, please touch us, and our experienced body of workers will help guide you along with your custom profile needs.Products DescriptionProduct namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM, GB

Contacta ahora

UNS S32760 is able to compete strongly with the 6% molybdenum “super austenitic” grades in some applications, as it has fewer amounts of Mo and Ni which drive up the base cost of the material. Although, 32760 has lower amounts when compared to “6% Moly” grades it still has higher contents of Cr, Ni, and Mo when referring to other alloys, these elements improve the intergranular and pitting corrosion resistance of the material.

Contacta ahora

309S stainless steel flat steel characteristics: can withstand 980 repeated heating, with high temperature strength and oxidation resistance, carburizing resistanceProduct Parameter:ITEMStainless Steel Flats bar SizeWidth 3-500mm;Thickness0.3-120mm;Length:1000-600mm(or as your request)SurfaceBlack, pickled, bright, ground as per customers' requirementFinish Hot rolled, cold drawn, hot forgedMaterial201.202.301.302.304.304L.310S.316.316L.321.430.430A.309S.2205.2507.2520.430.410.440.904Lect.

Contacta ahora

Type 309 is an austenitic chromium nickel stainless steel (.08% max carbon).Type 309is employed for parts requiring both corrosion and heat resistance and oxidation resistance up to 2000oF. Strength at elevated temperatures is similar to that of 18-8 Stainless Steels.This alloy posses excellent resistance to oxidation as well as high tensile and creep strengths at elevated temperatures.

Contacta ahora

321 stainless steel flat bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range.

Contacta ahora

316L stainless steel flat steel is mainly used for manufacturing pipe distribution materials in heat exchange equipment, and also used as boiler outage protection device and other chemical equipment and connecting parts between structural parts. The main uses of the stainless steel rod are as follows:1. Used for making pipes to withstand hydraulic test.2. Used for making high pressure seamless steel pipe.3. Parts for making fertilizer equipment.4. For the manufacture of conventional weapons, barrels, shells and magazines.5. It can replace 30CrMnSi for geological drilling.6.

Contacta ahora

317l bars & rods is providing better creep, pressure to rupture, high tensile energy, and weldability. due to first-rate yield electricity, it has great thermal stability that can be utilized in accelerated temperature service. it has advanced corrosion resistance to corrosive acids together with acetic, formic, sulfurous, citric, and tartaric acid.

Contacta ahora

Ti in 321 stainless steel exists as a stabilizing element, but it is also a heat-strong steel, which is much better than 316L in the aspect of high temperature.321 stainless steel has good abrasion resistance in organic and inorganic acids at different concentrations and temperatures, especially in oxidizing media, and is used for the manufacture of wear-resistant acid containers and wear-resistant equipment lining, conveying pipeline.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226,&n

Contacta ahora

416 Stainless Steel Flat Bar416 Stainless Steel Flat Bar is a free-machining version of martensitic stainless metal with the addition of sulphur or selenium that was once designed for multiplied machinability. 416 with the addition of sulfur makes it a free machining stainless steel. Heat therapy will harden 416 as nicely as amplify energy and hardness. This grade has higher machining. The fabric can be hardened by using warmth remedy to greater electricity and hardness levels.

Contacta ahora

Stainless Steel 317 Square Bars & Rods have excellent yield strength and tensile strength, which is suitable for cold working and annealed condition appliance. It has nickel and low carbon content to provide high formability and excellent corrosion resistance to alkaline compounds. SS 317 Bars & Rods is austenitic stainless steel non-magnetic in nature, less conductivity to electricity, and less brittle at low temperature.

Contacta ahora

Basic Info.Model NO.Steel SheetSpecial UseHigh-strength Steel PlateStockStockMOQ1tonSampleAvailableSmall OrderIt′s OkMaterialStock/ProductionServiceOEM/ODMOur ForwarderFocusing on Steel IndustryOur PackerMore Than Ten Years ExperienceOur SalesmanAbout Five Years ExperienceOur ComapnyAbout Five Years ExperienceOur AdvantageOne-Stop ServiceTransport PackageStandard Export Seaworthy Package, or as RequiredSpecificationThickness: 12mmOriginShanghaiHS Code7207225409Production Capacity4000tons/MonthProduct DescriptionProduct DetailsWidth1500-4050mmWall thickness8mm-300mmLength3000MM-15000MMInternati

Contacta ahora

I-beams are specially divided into normal i-beams, mild-responsibility i-beams and huge-flange i-beams. in line with the height ratio of flange and internet, it is divided into huge, medium and slim wide flange i-beams. the primary two are produced in size 10-60, this is, the corresponding peak is 10 cm-60 cm.

Contacta ahora

Stainless Steel I Beam (H-beam)1. Standard: AISI, ASTM, GB, JIS, BS, DIN2. Material: 201, 301, 304, 309S, 310S, 316, 316L, 321, 410, 430 & others3. Size: 100× 68× 4.5mm-630× 178× 15mm4. Surface: Annealed, pickled5. Technique: Welded6. Shape: H/I shape7. Applications: Widely used in all kinds of architecture and engineering structure, such as the beam, bridges, transmission tower, hoisting.8. Packaging: Standard export packing or according to customer's request11. Delivery Time: According to the quantity12. Payment: L/C or T/T13.

Contacta ahora

Incoloy 840 has the characteristics of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, easy installation, long service life, etc., widely used in all kinds of water tank, oil tank, acid and alkali tank, fusible metal melting furnace, air heating furnace, drying furnace, drying oven/oven, oven and hot press die device.

Contacta ahora

Nickel Alloy Incoloy 800HT PipeIncoloy 800 HT is composed of more aluminum and titanium. This gives 800 HT even greater resistance to high temperatures. Incoloy 800 HT is recommended for temperatures exceeding 1100° F, often in instances where stainless steels are subject to crack and creep. The Incoloy alloys are commonly used in high temperature environments, such as industrial furnaces, chemical and nuclear vessels, and heat-treating equipment.

Contacta ahora