Features and Benefits• Made from silver-coloured 304S15 stainless steel• Length of 300 mm• Width of 300 mm• Thickness of 1 mm• Density of 8 g/cm³• Hardness 92 HB• Thermal conductivity of 16.2 W/m at +100°C• Tensile strength of 520 Mpa• RoHS (Restriction of Hazardous Substances) compliant• Meets standards BS1449 pt 2 and BSEN 10088-2 for steel plate, sheet and strip• Comes without adhesive backingSpecificationsAttributeValueLength300mmMaterial304S15 Stainless SteelFormSolidWidth300mmThickness1mmDensity8g/cm³Hardness92 HBColourSilverThermal Conductivity16.2 W/m at 100°cAdhesive BackingNoTensile

Contacta ahora

2304 duplex stainless steel bar:Stainless steel is a production which not easy rust, acid resistance and corrosion resistance, so it is widely used in light industry, heavy industry, daily necessities and the decoration industry.

Contacta ahora

2304 Duplex Stainless Steel PlateDuplex 2304 is a 23% chromium, 4% nickel, molybdenum-free duplex stainless metal whose shape is a stability of ferritic and austenitic. It has common corrosion resistance comparable or higher than Alloys 304L and 316L however with yield energy almost double that of austenitic stainless steels.

Contacta ahora

321 stainless steel of Ti as a stabilizing element exists, but it is also a hot steel, in terms of high temperature is better than 316 l. 321 stainless steel in different concentration and temperature of organic acid and inorganic acid, especially in oxidizing medium has good abrasion resistance, used in the manufacture of the lining of wear resistant acid containers and equipment and pipelines.

Contacta ahora

321 stainless steel flat bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range.

Contacta ahora

430 stainless steel is a type of ferritic stainless-steel that consists of chromium, which gives it its corrosion-resistant properties. the primary alloying element in 430 stainless-steel is chromium, generally starting from 16 to 18 percentage. it additionally has a low carbon content material, which improves its weldability.430 stainless-steel bars are generally utilized in various packages due to their desirable mixture of corrosion resistance, formability, and affordability.

Contacta ahora

Grade 310s Stainless Steel is the standard "18/8" stainless; it is the most versatile and most widely used stainless steel, available in a wider range of products, forms and finishes than any other.

Contacta ahora

Type 309 is an austenitic chromium nickel stainless steel (.08% max carbon).Type 309is employed for parts requiring both corrosion and heat resistance and oxidation resistance up to 2000oF. Strength at elevated temperatures is similar to that of 18-8 Stainless Steels.This alloy posses excellent resistance to oxidation as well as high tensile and creep strengths at elevated temperatures.

Contacta ahora

The 304L Stainless Steel Flat Bar is an austenitic metal that is made up of 18 percent chromium and 8 percent nickel. The carbon maximum for this grade of metal is 0.030 percent. This alloy is widely used because of its versatility. It is the most used stainless steel alloy in its family. 304L stainless steel is highly resistant to corrosion, even intergranular corrosion, which is caused by stress relieving or welding. Its low level of carbon makes it ideal for the majority of welded construction operations that use service temperatures that are limited to 800 degrees F.

Contacta ahora

316 Stainless Steel Flat Bar: 316 Stainless is ideally suited for corrosion resistance against a wide range of chemical and acidic corrodents, and marine environment applications. Typical uses of 316 Stainless include food production, pharmaceutical equipment, furnace parts, heat exchangers, valves and pumps, chemical equipment, and parts for marine use.

Contacta ahora

Stainless Steel UNS S20200 Flat Bars has related mechanical properties as liken to 304 Stainless Steel, but its capability to fight corrosion is less to some extent as relate to AISI 304 grade in chloride atmosphere. In spite of lower toughness and less corrosion-resistant, it offers low-cost alternate to SS 304 in food processing and kitchenware field applications.

Contacta ahora

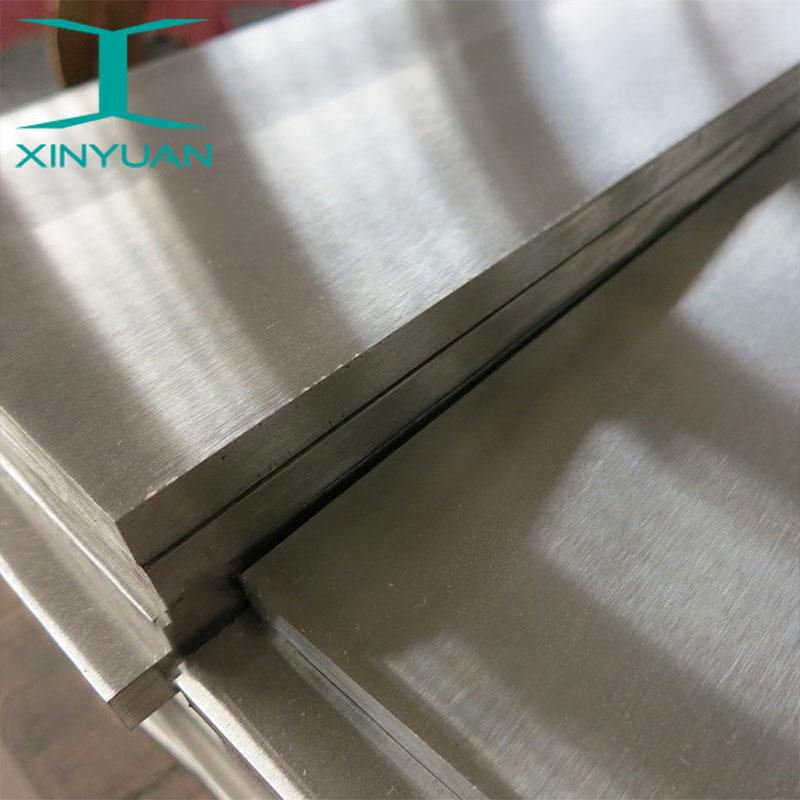

Product parameters:Grade201/202/301/303/304/304L/316/316L/321/310S/401/409/410/420J1/420J2/430/439/443/444/2205/2507Surface Finish2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, ectStandardJIS/SUS/GB/DIN/ASTM/AISI/ENTechniqueCold Rolled; Hot RolledThickness0.3-4mm cold rolled; 3-16mm hot rolled; Customized according to customer requirementsWidth1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mmApplicationInterior/Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure;ShipbuildingLead Time7-15 working days after the receipt of 30% depositP

Contacta ahora

Thickness0.3-10mmLength: 2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm, etcWidth 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etcStandard:ASTM,AISI,JIS,GB, DIN,ENSurface: BA,2B,NO.1,NO.4,4K,HL,8KApplication: It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc.Certification: I

Contacta ahora

316TI is a metallic material that is added to SUS316 steel to improve the resistance to intergranular corrosion.

Contacta ahora

A 310s stainless-steel bar is a sort of stainless steel alloy that carries high degrees of chromium, nickel, and a mild quantity of carbon. the "310s" designation refers back to the unique grade of stainless-steel and indicates that it contains 25-28% chromium and 19-22% nickel.310s chrome steel is known for its outstanding oxidation resistance at high temperatures and its potential to face up to thermal biking.

Contacta ahora

2507 Super Duplex Stainless Steel BarsAlloy 2507 is a duplex stainless steel, a super duplex stainless steel composed of 25% chromium, 4% molybdenum and 7% nickel.Main components: 25Cr-7Ni-4Mo-0.27N2507 is a ferritic-austenitic (duplex) stainless steel, also called duplex stainless steel, which has excellent resistance to pitting, crevice corrosion and uniform corrosion.Application areas: pulp and paper industry, seawater desalination, flue gas purification, heat exchangers, chemical tanker piping systems, seawater systems, etc.Product Parameter:Equivalent MaterialsSAF2507, EN 1.4410, UNS S327

Contacta ahora

Super Duplex 2507 PipeSuper Duplex 2507 Pipe is a exquisite duplex cloth made steel pipe. The high-quality duplex is an alloy of chromium, molybdenum and nickel. The fabric has very excessive corrosion resistance houses and is resistant to pitting corrosion, crevice corrosion and uniform corrosion as well. The Alloy 2507 Seamless Pipes are produced via a technique referred to as the cold drawing. Cold drawn pipes are seamless or have clean surfaces. They are proper to be used in aesthetic searching and unique applications.

Contacta ahora

316L Super Austenitic Stainless Steel316L Super Austenitic Stainless Steel Scope of application:Corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, which can be used in harsh conditions; Excellent work hardening (non-magnetic).

Contacta ahora

Duplex 2507 Stainless Steel PlateAlloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion.

Contacta ahora

Duplex 2205 PlateDuplex 2205 Plate is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. Duplex 2205 Plate is the most broadly used duplex stainless metal grade and is characterised via excessive yield strength, double that of the standard austenitic stainless steel grades.

Contacta ahora

AISI 329 Duplex Stainless Steel Plate belongs to a specification of duplex steel grades.

Contacta ahora

2507 Stainless Steel Pipe is a super duplex grade for which elements chromium, nickel and molybdenum are the primary alloyants.

Contacta ahora

2205 Duplex Stainless Steel Bar is the most widely used duplex (ferritic/austenitic) stainless steel grade. It findsapplications due to both excellent corrosion resistance and high strength.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contacta ahora

S32760 Super Duplex Forged Bar can be produced by following specification standard ASTM A276.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contacta ahora