Type 301 is a chromium nickel austenitic stainless steel capable of attaining high strengths and ductility by cold working. It is not hardenable by heat ...Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contacta ahora

Type 301 is an austenitic chromium-nickel stainless steel that is available in the annealed and cold worked conditions. In the annealed condition, Type 301 offers the highest level of stretch formability of any stainless steel and in the heavily cold worked condition offers the highest strength level of any 300 series stainless steel. Type 301 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contacta ahora

Stainless steel grade 301 is a commonly available austenitic stainless with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers.

Contacta ahora

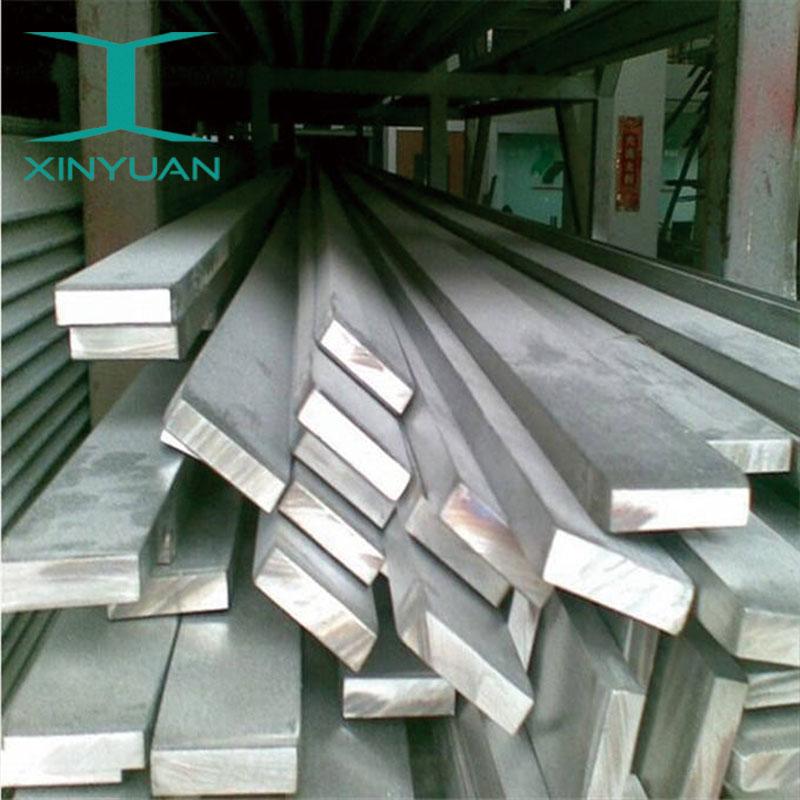

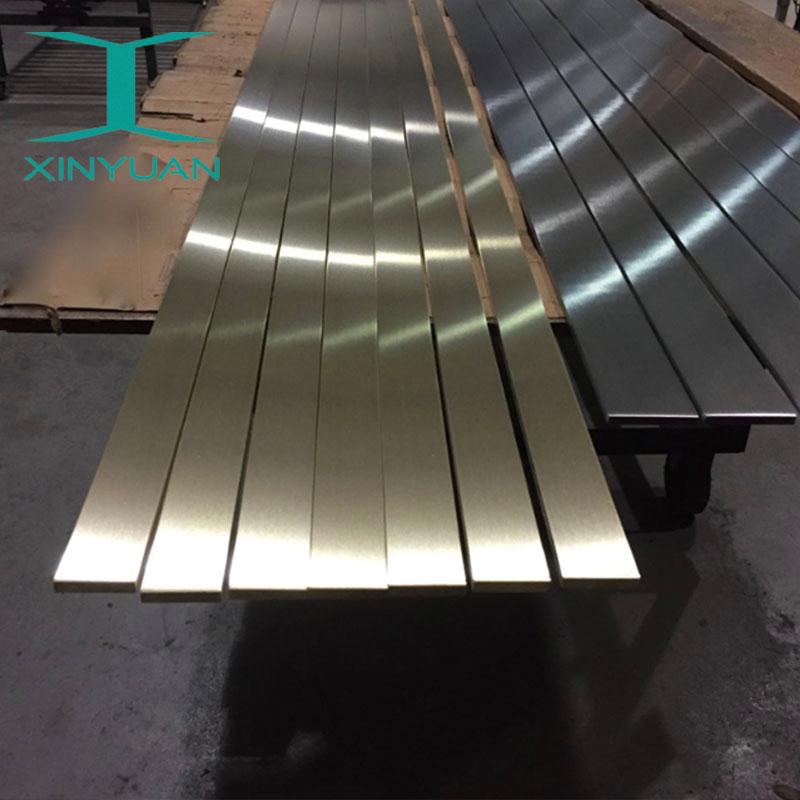

Material GradeSS 304ShapeFlatApplicationConstructionMaterialSSThickness3 mm to 200.00 mmWidth6 mm to 2000 mmMinimum Order Quantity50 kgProduct DescriptionWe are the pioneers in manufacturing and supplying the finest quality Stainless Steel Flat / Patta. This specially designed steel flat/patta is made using top quality stainless steel, which makes them durable and high in performance.

Contacta ahora

416 Stainless Steel Flat Bar416 Stainless Steel Flat Bar is a free-machining version of martensitic stainless metal with the addition of sulphur or selenium that was once designed for multiplied machinability. 416 with the addition of sulfur makes it a free machining stainless steel. Heat therapy will harden 416 as nicely as amplify energy and hardness. This grade has higher machining. The fabric can be hardened by using warmth remedy to greater electricity and hardness levels.

Contacta ahora

Flat welding flanges are suitable for pipeline systems with relatively low pressure levels and no serious pressure fluctuations, vibrations and shocks.

Contacta ahora

The most widely used of the stainless and heat resisting steels, 304 offers good corrosion resistance to many chemical corrodents as well as industrial atmospheres.304 Stainless Steel Flat Bar has very good formability and can be readily welded by all common methods.

Contacta ahora

316 Stainless Steel Flat Bar: 316 Stainless is ideally suited for corrosion resistance against a wide range of chemical and acidic corrodents, and marine environment applications. Typical uses of 316 Stainless include food production, pharmaceutical equipment, furnace parts, heat exchangers, valves and pumps, chemical equipment, and parts for marine use.

Contacta ahora

309S stainless steel flat steel characteristics: can withstand 980 repeated heating, with high temperature strength and oxidation resistance, carburizing resistanceProduct Parameter:ITEMStainless Steel Flats bar SizeWidth 3-500mm;Thickness0.3-120mm;Length:1000-600mm(or as your request)SurfaceBlack, pickled, bright, ground as per customers' requirementFinish Hot rolled, cold drawn, hot forgedMaterial201.202.301.302.304.304L.310S.316.316L.321.430.430A.309S.2205.2507.2520.430.410.440.904Lect.

Contacta ahora

301 stainless steel strip is a kind of metastable austenitic stainless steel, which has a completely austenitic structure under the condition of full solution. Among the stainless steels, 301 is the steel that is most easily strengthened by cold deformation. Cold deformation can increase the strength and hardness of the steel and retain sufficient plasticity and toughness. In addition, this steel has good rust resistance under atmospheric conditions.

Contacta ahora

The 304L Stainless Steel Flat Bar is an austenitic metal that is made up of 18 percent chromium and 8 percent nickel. The carbon maximum for this grade of metal is 0.030 percent. This alloy is widely used because of its versatility. It is the most used stainless steel alloy in its family. 304L stainless steel is highly resistant to corrosion, even intergranular corrosion, which is caused by stress relieving or welding. Its low level of carbon makes it ideal for the majority of welded construction operations that use service temperatures that are limited to 800 degrees F.

Contacta ahora

321 stainless steel flat bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range.

Contacta ahora

Stainless steel 301 Square Bar include 17% chromium and 7% nickel, which give excessive tensile strength as much as 1800mpa. these ss 301 bars are in particular used in plane, rail vehicle additives, and architectural structures.

Contacta ahora

410 stainless steel flat steel is widely used in decorative pipe, kitchenware, products with pipe. Food technology, sugar and wine making equipment. Beer piping. Cooling equipment. Water treatment equipment, electric transportation equipment, mechanical automation equipment, medical equipment, automobile accessories. Boiler auxiliary machine. Petrochemical, printing and dyeing equipment, heat exchanger, water supply and other industries.

Contacta ahora

Stainless Steel UNS S20200 Flat Bars has related mechanical properties as liken to 304 Stainless Steel, but its capability to fight corrosion is less to some extent as relate to AISI 304 grade in chloride atmosphere. In spite of lower toughness and less corrosion-resistant, it offers low-cost alternate to SS 304 in food processing and kitchenware field applications.

Contacta ahora

Type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304. Nickel is replaced by additions of manganese and nitrogen. It is non-hardenable by thermal treatment, but may be cold worked to high tensile strengths. Type 201 is essentially nonmagnetic in the annealed condition and becomes magnetic when cold worked.

Contacta ahora

310 stainless-steel hex bar may be categorically said that metal bars are one of the middle components of any manufacturing industry or for that matter any industry that is based on machineries.

Contacta ahora

Introduction of stainless steel bar fabric, application scope, nice managementmaterial :304, 304l, 321, 316, 316l, 310s, 630,commonplace substances are 201, 202, 301, 304, 303, 316, 316l, 304l, 321, 2520, 1cr13, 2cr13, 3cr13, dual-section steel, antibacterial metal and other materials!

Contacta ahora

301 stainless steel bar is a metastable austenitic stainless steel with complete austenitic structure under the condition of full solution.

Contacta ahora

Our 301 Stainless Steel Welded Pipes are made of 301 stainless steel, which can exert strong anti-corrosion properties in air or chemically corrosive media, and are often used in production, chemical equipment and other fields. They have a smooth surface and good corrosion resistance, which is not caused by surface treatment such as electroplating, but takes advantage of the inherent surface properties of stainless steel.

Contacta ahora

316L stainless steel flat steel is mainly used for manufacturing pipe distribution materials in heat exchange equipment, and also used as boiler outage protection device and other chemical equipment and connecting parts between structural parts. The main uses of the stainless steel rod are as follows:1. Used for making pipes to withstand hydraulic test.2. Used for making high pressure seamless steel pipe.3. Parts for making fertilizer equipment.4. For the manufacture of conventional weapons, barrels, shells and magazines.5. It can replace 30CrMnSi for geological drilling.6.

Contacta ahora

Introduction of stainless steel bar material, application scope, quality managementMaterial :304, 304L, 321, 316, 316L, 310S, 630,Common materials are 201, 202, 301, 304, 303, 316, 316L, 304L, 321, 2520, 1Cr13, 2Cr13, 3Cr13, dual-phase steel, antibacterial steel and other materials!

Contacta ahora

301 Stainless Steel Coil301 stainless metal coil is a kind of hardenable austenitic stainless metal with excessive strength, reasonable corrosion resistance and correct formability.

Contacta ahora

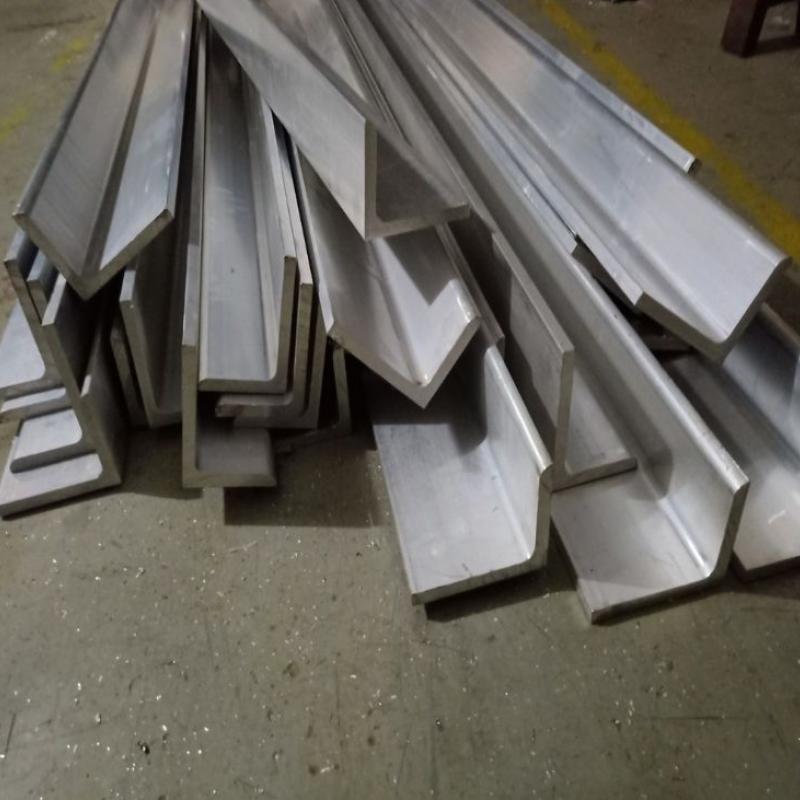

Popular for its corrosion resistance, stainless steel rod is used in a wide range of applications including the construction of building foundations, bridges, and marine environments.We have black bright surface, and different materials such as 201 304 304L 316 316L 2205 2507 430 420 410 for you to choose.Standard:ASTM,AISI,JIS,GB, DIN,ENCertification:SGS,ISO,ROHSLength:2000-12000mm,or as requiredShape:Round bar/square bar/hexagonal bar/flat barRound bar:3mm--800mm, etcHexagonal:Size : 2mm~10mmSquare bar:Size : 4mm*4mm~100mm*100mmFlat bar:Tickness : 2mm~100mmWidth:10mm~500mmHeat Treatment

Contacta ahora